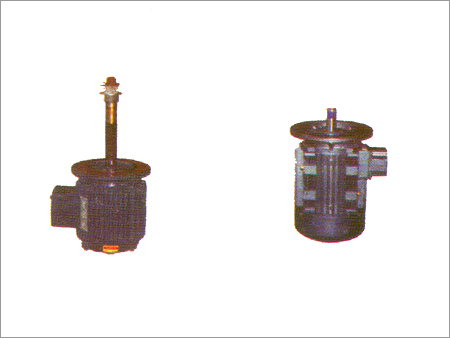

About Cooling Tower Motors

We feel glad to introduce ourselves as one of the leading manufacturers and suppliers of a broad assortment of Cooling Tower Motors. To assemble this motor, our ingenious team of professionals makes usage of the best in class components and progressive techniques in complete tandem with universally accepted standards of quality. It is used to install in cooling towers. Besides, this Cooling Tower Motors is available with us in various technical specifications at market leading rates.

Features:

- Low power consumption

- Highly efficient

- Robust construction

- Smooth surface finish

Highly Efficient Squirrel Cage Motors for Cooling TowersThese motors utilize squirrel cage induction designs known for durability and reduced maintenance. Their high efficiency minimizes energy consumption, meeting industrial demands while offering significant operational cost savings.

Versatile Installation and Protection FeaturesWith options for both foot and flange mounting, and an IP55 rating, these motors are safeguarded against dust and water ingress. The Totally Enclosed Fan Cooled (TEFC) design enhances longevity even in challenging cooling tower environments.

Optimized for Performance and LongevityDouble-sealed ball bearings and a sealed bearing structure ensure extended lifecycle and smooth operation. High starting torque and low noise levels contribute to an improved user experience and reliability in continuous running applications.

FAQs of Cooling Tower Motors:

Q: How do Cooling Tower Motors ensure high efficiency and reliability?

A: Cooling Tower Motors utilize squirrel cage induction technology, double-sealed ball bearings, and advanced TEFC protection. These features minimize energy losses, reduce maintenance, and ensure reliable long-term operation in demanding industrial settings.

Q: What mounting options are available for these motors and which should I choose?

A: These motors offer both foot-mounted and flange-mounted configurations, allowing flexibility based on your cooling towers design. The ideal mounting depends on the structure and space of your installation environment.

Q: Where are Cooling Tower Motors commonly used?

A: Cooling Tower Motors are primarily used in thermal power plants, HVAC systems, chemical plants, and industrial cooling towers throughout India, wherever reliable air-cooling and water protection are critical.

Q: When should the motor be serviced or inspected?

A: Routine inspection is recommended every 6-12 months, depending on operating conditions. Regular maintenance preserves efficiency and prevents premature wear, especially in highly demanding environments.

Q: What is the benefit of the IP55 rating and TEFC protection feature?

A: The IP55 rating combined with the Totally Enclosed Fan Cooled (TEFC) design protects motors from water jets, dust, and contaminants, extending operational life and reducing the risk of downtime due to environmental factors.

Q: How does the speed choice (960 RPM or 1440 RPM) impact performance?

A: Speed selection impacts cooling efficiency and application compatibility. 960 RPM motors offer quieter operation and improved longevity, while 1440 RPM provides faster cooling for environments requiring rapid heat dissipation.